Here at Vesta Smart Packaging, we pride ourselves in being at the forefront of an innovative approach to packaging that will help eliminate single-use plastics. Our model is centred on our smart packaging, which monitors its contents and automatically orders compostable or recyclable refill packs which are delivered directly to the customer just before they run out of a product.

But we know there are other approaches to the plastic problem, and a big one is refill solutions or dedicated refill stores. We’ve written before on this [link], and while we want these to succeed – the world needs A LOT of successful solutions if the plastic problem is ever going to be tackled – but we are concerned. There probably isn’t anyone who wouldn’t rather we all threw less plastic packaging away, it’s the last non-contentious issue out there, but we also know that people feel they have less and less free time. Refill solutions ask consumers for more of their time and organisation to tackle the plastic problem. While we are happy to see so many trying refill, there are some disturbing signs that the novelty is already wearing off, and that people aren’t willing to invest the extra effort over the long haul.

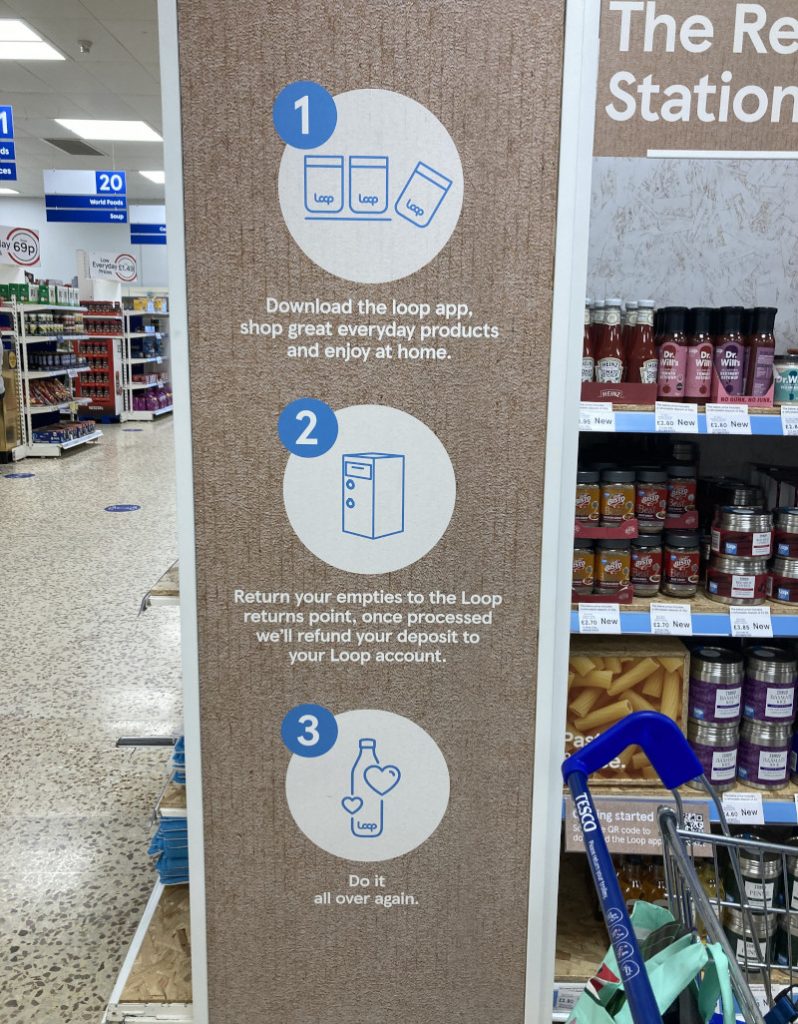

The big name in refill is Loop, which has been trialled in my local Tesco store for several months. Tesco dedicated an entire aisle to Loop products, with a display at the end that explained the premise of Loop and an aisle full of Loop goods. The aisle had an array of Loop products, ready to buy in their reusable containers, pictured here.

Near the entrance of the store was a Loop returns box, where Loop users could return their empty containers and receive their deposit back on a printed receipt with a QR code. The customer then buys the product again and uses the receipt to take the deposit off their shopping bill. This model means that the customer buys the Loop container and replaces it with a refilled container of the same kind when they return and re-buy their product. It’s simple to follow and clearly marked.

When I went to pay for my shopping, I chose a checkout where there were several staff members nearby. Having an interest in Loop, I asked them about their experience of customers using Loop and was told that there was a lot of interest initially, but it had faded after the first few weeks. One checkout staff member told me that they only get one or two people a week using Loop, while another, newer, member of staff said that they had never put a Loop product through the till. I asked them why they thought this was happening, when the store had dedicated so much space to promoting Loop and had a screen and clear instructions explaining how Loop worked.

One member of staff suggested that it was simply too much to ask that customers remember to pack their empty containers to come for a shopping trip, when many struggled to remember to bring their reusable shopping ‘Bags for Life’. Another guessed that customers didn’t necessarily run out of product in a way that coincided with their weekly shop and therefore did not bring the empty containers back and instead topped up their staples with the standard versions of the product, as they did not want multiple containers for the same product, with multiple deposits.

Whatever the reason for this decline in adoption and use, Tesco and Loop are not alone in experiencing this drop-off in customer engagement. Madeleine Cuff writes, in MSN Money, ‘People aren’t coming anymore’: Refill stores face crisis as shoppers lose interest in zero-waste lifestyles which observes a very similar phenomenon that happened in with other refill solutions.

She observed that shoppers abandoned zero-waste shopping during the pandemic and named several UK-based refill stores that were forced to close due to a lack of interest, with one owner stating, “I went from delivering 30-40 orders a week to two or three … I actually went past two houses on my way to my shop on Saturday who I used to deliver to, and they both had supermarket delivery vans parked outside them … There’s a lot of people who talk about being more environmentally conscious, but don’t actually follow through with that”.

Another owner commented that, “it’s not that people are buying less. It’s that people aren’t coming anymore, Everyone is busier now. They don’t have time… it’s quicker just to run into Sainsbury’s”.

Both Tesco employees and the refill store owners mention convenience as their main problem with retaining customers. With the end of the pandemic, the return to normal working hours and the fast pace of life, standard refill models do not seem to be able compete with other demands on people’s time.

However, Vesta has taken this into account. We have designed a recycling model that makes it easier for people to shop, easier to recycle and more convenient to use.

Our Vesta Smart Packages are exactly that: smart. They are aware of the amount left in a container and connect to our online platform to tell the customer how much is left. If the customer doesn’t have time to check the online platform, they don’t need to worry! Our system will automatically order compostable or recyclable refill packs and send them directly to the customer, just before they run out.

Unlike standard refill systems, our users don’t need to think about Vesta, they can simply forget and refill their smart containers when the refill packages arrive at their home or business. At Vesta, we believe that refill is the first step in the right direction, we do have to change behaviours if we’re to tackle the plastic problem. We also think that to solve the problem of single-use plastics, a solution must offer a real and sustained incentive to keep using it – not a cost.

Vesta technology has been designed with the customer’s needs in mind. Please get in touch if you’d like to understand how we can help your company create a more engaging approach to delivering your product to your customers and providing the vital path to eliminating single-use plastics.